At Air Systems Engineering, we specialize in the removal of sticky particulate, i.e. liquid asphalt, condensable hydrocarbons, and blue haze (sub-micron) particulate in aerosols. Our partnership with Kimre™ enables us to provide mist eliminators that efficiently remove 99.9% of particles which are smaller than 1 micron.

The introduction of Kimre™ patented high-performance, interlaced mesh structure revolutionized the technology of process fluid separation and air pollution control. Kimre™ mist eliminators reduce operating pressure drop, improve vessel throughput, and lower maintenance costs.

B-Gon® Mist Eliminators

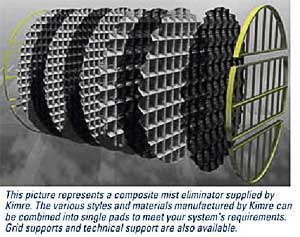

Kimre’s uniquely structured mesh combats the weaknesses of the wire mesh currently on the market. This allows Kimre’s engineers in conjunction with Air Systems Engineering to design for the highest level of performance at any particle or mist size.

Kimre’s uniquely structured mesh combats the weaknesses of the wire mesh currently on the market. This allows Kimre’s engineers in conjunction with Air Systems Engineering to design for the highest level of performance at any particle or mist size.

Features and Benefits of B-GON® Mist Eliminators:

- Wide availability of materials and styles results in a unique solution for every application

- Composite pads are available

- Can operate at the highest gas velocities based on the largest fiber diameters in the industry

- High void spaces and large fiber diameters contribute to the highest resistance to fouling.

- Highest collection efficiency of ANY material: 99+% @ 1 µm

- Pads are supplied in sizes from 4" diameters to ANY size

- Material is cleanable & reusable with extended service life in the most harsh environments

- Coalescers can be made from the finest styles of material

- Support systems available

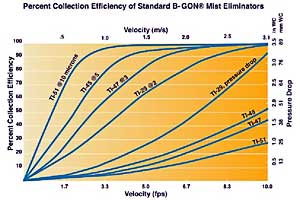

The graph displays the collection efficiency and clean operating pressure drop of some standard pad designs operating in an air/water environment under ambient conditions. Please contact Air Systems Engineering to discuss your particular application and determine the best design for you.

The graph displays the collection efficiency and clean operating pressure drop of some standard pad designs operating in an air/water environment under ambient conditions. Please contact Air Systems Engineering to discuss your particular application and determine the best design for you.

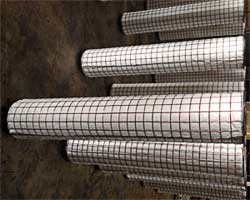

Candle Fiber Bed Coalescing Filters

Fiber bed filters are used to trap, collect and remove liquids and soluble particulate matter suspended in a gas stream. Mist laden gas passes in a horizontal direction perpendicular to the one side of the fiber bed and cleaned gas exits from the opposite side. As the particles try to pass through the fiber bed, they are trapped and held by the fibers. The collected particles are coalesced into drops on the filter’s fiber surface and drain by gravity. Particles are collected by a combination of impaction, interception, and Brownian movement.

Kimre™ Candle Fiber Bed Filters are available in standard or custom-designed configurations to fit new or existing systems in the field.

Features and Benefits of the Brownian Diffusion Candle Filter

- Using high efficiency media, the Kimre Candle Fiber Bed mist eliminator can achieve effiencies greater than 99.9% on particles smaller than 1 micron.

- MAT and roving media allow custom designed composite beds.

- Designed to meet the specific requirements of each plant

Kimre™ offers exact replacements of existing elements in many plants.

Kimre™ offers exact replacements of existing elements in many plants.

Features and Benefits of the Impaction Candle Filter

- Custom-designed filters for any vessel

- High flow per filter

- Enhanced drainage capacity

- Easy to clean, reusable media

- Designed to meet the specific requirements of each plant